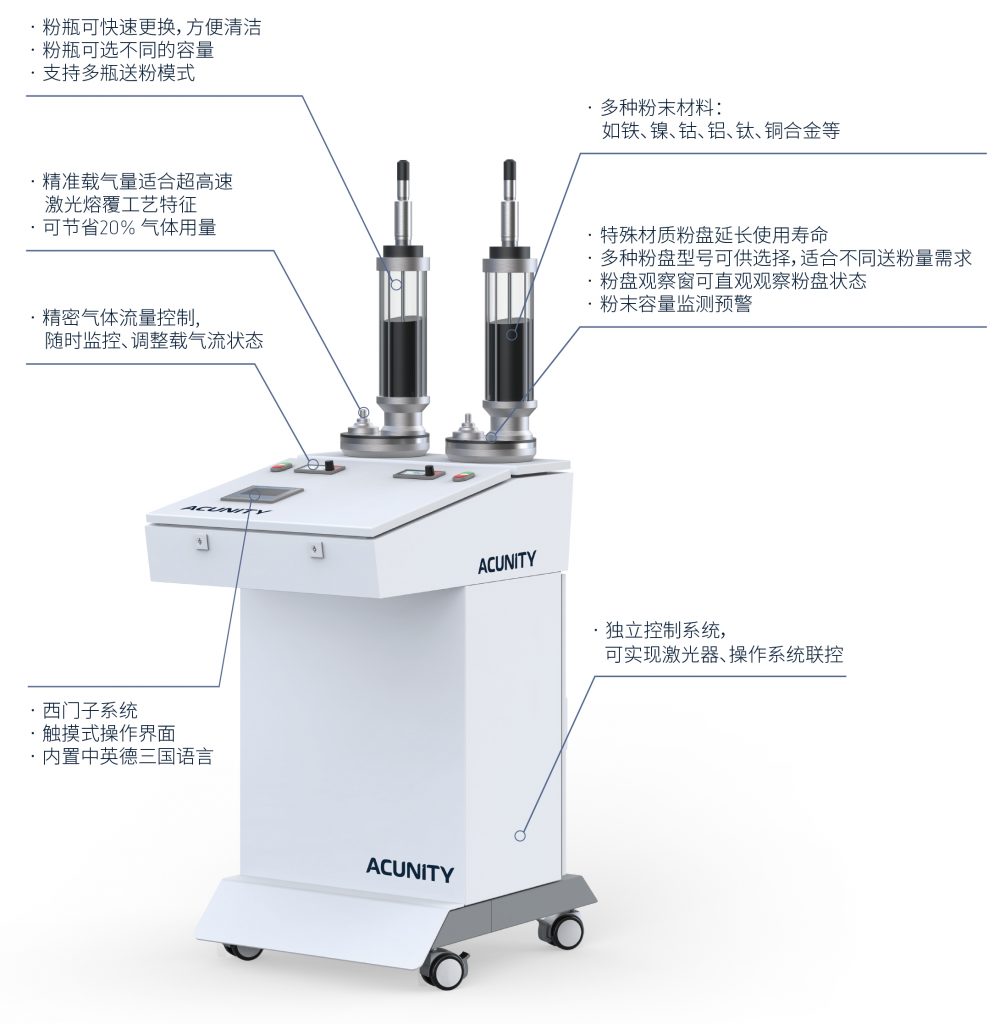

Powder feeder

To meet the powder feeding accuracy demanding requirements of laser cladding and ultra-high-speed laser cladding, ACUNITY developed infinity series powder feeders originated from Germany, which can not only ensure the stability of high power and large powder feeding volume, but also can play its unique high-precision micro powder feeding function in the precision powder feeding process.

The modular design of the infinity-p200/infinity-p400 powder feeder also provides users with enough space to choose from a single bottle to a maximum of four bottles according to the demand of the process powder feeding volume. The powder bottle can also be fully customized, divided into 0.75L, 1.5L, and 5L, to meet the demand for ultra-high-speed laser cladding. The powder feeder is designed with special sealing, which can save 10-20% of gas consumption compared with similar products in the market. The stirring function in the powder bottle can be set at intervals or continuously through the built-in touch screen operator interface. Each powder bottle is equipped with a powder quantity detection sensor, which automatically prompts when the powder quantity is insufficient, making it convenient for users to replenish the powder. The special plating treatment of the powder tray makes it more wear-resistant and durable, reducing the frequency of consumables replacement. In addition to the standard powder feeder series, we can also develop customization according to your needs for easy integration into various types of coating systems.

INFINITY-EHLA Powder Feeder

For ultra high-speed laser cladding tailored