ILC system

ACunity introduces the advantages of high integration, high precision, and high adaptability of the inner cladding processing system, which can quickly achieve efficient and high-quality laser processing of the internal surfaces of different types of parts, with accessibility that is difficult to obtain with traditional optical heads and can perform a variety of processing such as internal hole fusion, repair, hardening, welding, and additive manufacturing. Furthermore, the system can be equipped with different sensing systems according to the application requirements to ensure the stability of the processing quality and realize the online monitoring of the processing process. At the same time, we can customize particular specifications of inner wall processing equipment for customers. Together with ultra-high-speed laser cladding technology, we can complete the simultaneous processing of inner and outer walls of oil cylinders, columns, and other products.

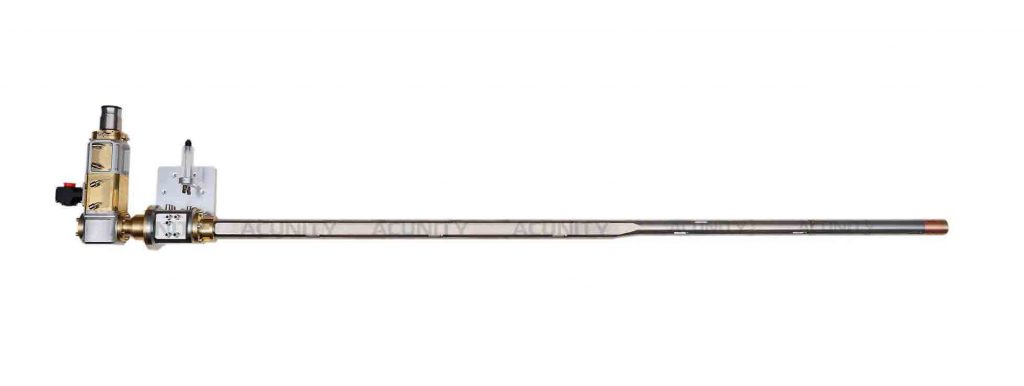

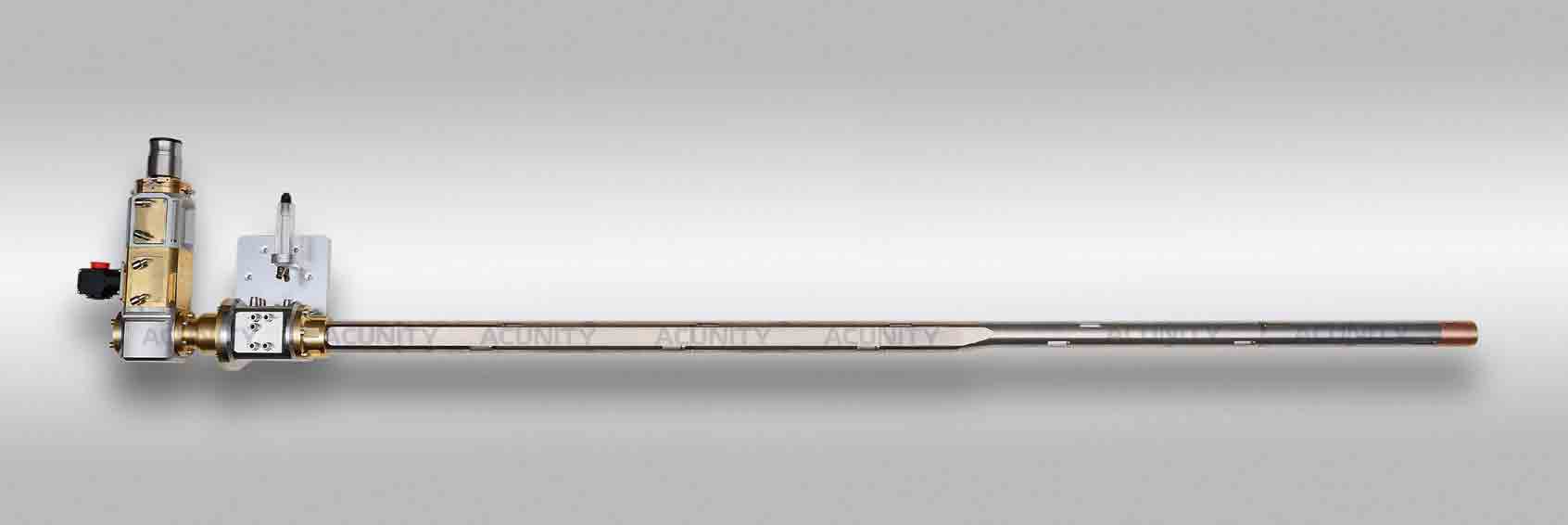

▏Inner wall of the laser processing system

● High precision powder feeding nozzle for inner cladding, adjustable powder flow focus above 1mm

● The inner wall of the laser head is highly integrated: the cooling system, powder feeding system, the laser beam accurately guide

●Maximum extension length 3m, fit a long time operation

●Suitable for most small tube inside diameter Φ33mm

●Can be used with CNC machines, robot system integration

Load 1,500 kg

Can be for a maximum of 1,500 kg to be machined parts

for EHLA

Not to the inner wall of the cladding of the optical head

The precise structure of the cooling system, powder feeding system,

The laser beam accurately guide.

Energy efficiency

System the efficient use of resources and energy consumption,

Cost-saving, environment-friendly.

The standard components

Use industry-proven standards parts

low & zero maintenance

Modular construction

A plurality of clamping solutions, online monitoring module development

Optional.

Powerful operation software

Powerful Operation, Easy user interface

Quickly generate a walking path.

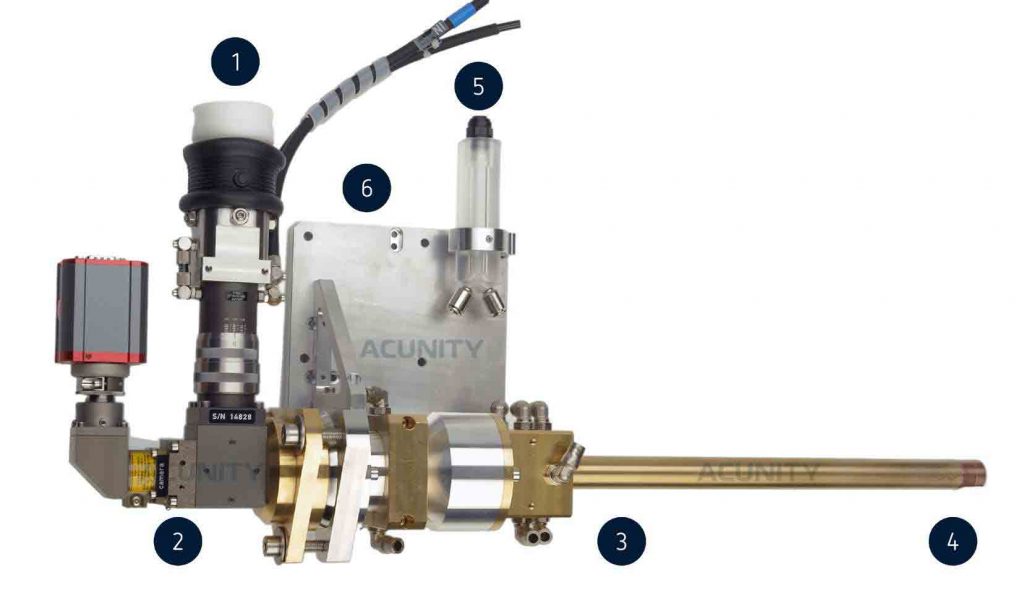

① Optical fiber socket

② The collimator with the coaxial CCD optical Assembly

③ The machining head of the body, the integrated optical circuit, gas, water and powder feeding channel, and the corresponding adjustment mechanism

④ Beam and the powder focusing Assembly

⑤ Powder shunt

⑥ Install the connecting plate

ACunity and IXUN GmbH (a spinoff of Fraunhofer ILT) jointly developed a series of models of inner laser processing heads, realizing the integration of optical, water, gas, and powder paths. The maximum Optics length can reach 3m, Which means 6m Processing length from both sides of the pipe components, adapting to the minor internal diameter of Φ33mm, which can solve the technical problems of internal wall laser processing of many slim diameter parts and complex components with restricted locations. It can solve the technical difficulties of laser processing of many thin and long-diameter parts and laser processing of complex components in restricted positions and again challenges the new limit of internal wall laser precision processing. Replacing the front nozzle can meet the processing requirements of laser cladding, repair, welding, and hardening and quenching processes for different parts' inner walls and cavities. Due to the limited visibility of the inner hole processing process, the optic head can be equipped with an optional vision sensing and lighting system

▏Multiple types of the inner wall of the optical head

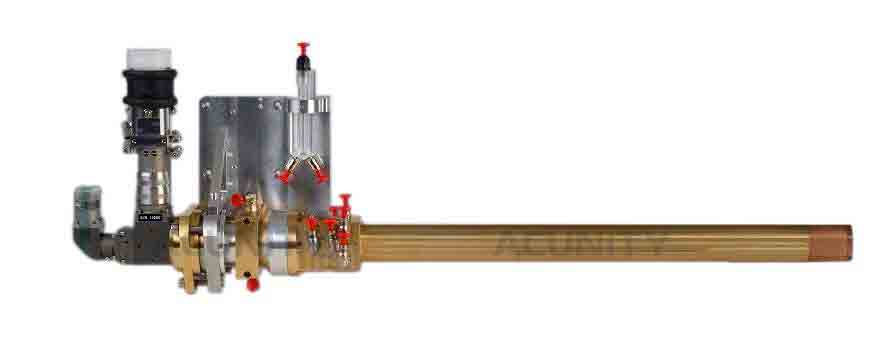

Standard type inner wall of the optical head

Meet the most of the products of the inner wall of the laser cladding and hardening application requirements

• Extension length: 1m, 1.5 m (one-sided)

• Adaptation to pipe diameter: minimum Ф55mm

• Have the function: laser cladding, laser hardening

Multifunctional inner wall of the optical head

Equipped with different type of powder feeding nozzle, can achieve a variety of the inner wall of the laser machining process

• Extension length: 1m, 1.5 m (one-sided)

• Adaptation to pipe diameter: minimum Ф100mm depending on the nozzle type

• Have the function: laser cladding, additive manufacturing, laser hardening, laser welding

Rotatable inner wall of the optical head

The optical head can be rotated to meet the non-rotating part of the inner wall of the laser cladding processing

• Extension length: 1m, 1.5 m (one-sided)

• Adaptation to pipe diameter: minimum Ф55mm

• Have the function: laser cladding, laser hardening

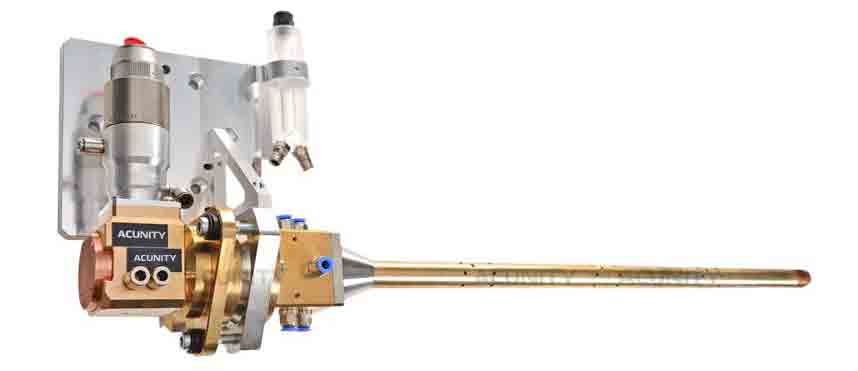

Ultra-small inner wall of the optical head

Meet the small-diameter part of the inner wall of the laser cladding processing application needs

• Extension length: 0.5 m, 0.8 m (one-sided)

• Adaptation to pipe diameter: minimum Ф33mm

• Have the function: laser cladding, laser hardening

Front replaceable modular inner wall of the optical head

Meet the diameter, change in length of more products or more types of machining parts needs

• Extension length: 1m, 1.5 m (one-sided)

• Adaptation to pipe diameter: minimum Ф55mm

• Have the function: laser cladding, laser hardening

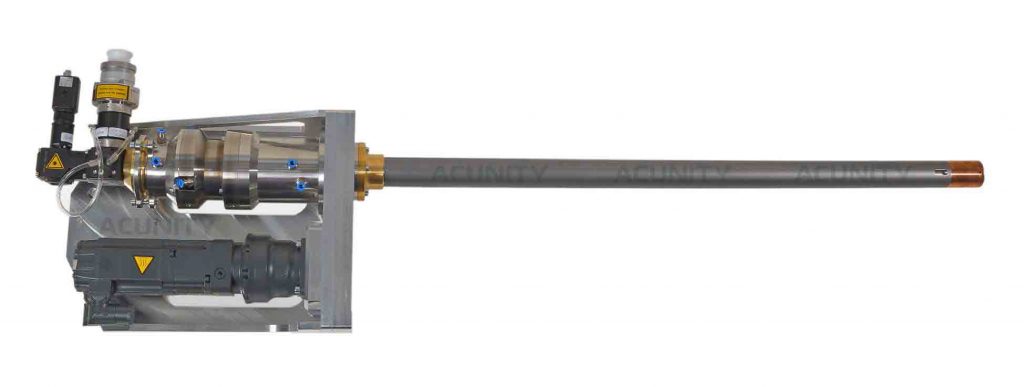

Ultra long type of the inner wall of the optical head

To meet the maximum length of the part of the inner wall of the processing, double-sided processing of the maximum length can be up to 6m

• Extension length: 2m, 3m (one-sided)

• Adaptation to pipe diameter: minimum Ф55mm

• Have the function: laser cladding, laser hardening

▏Variety of sensor integration system, to achieve inner wall of the cladding process temperature, surface state online monitoring

▏Different material of lightweight design, ensure the remote processing of high stability

Copper alloy

Titanium alloy