LMDCAM software

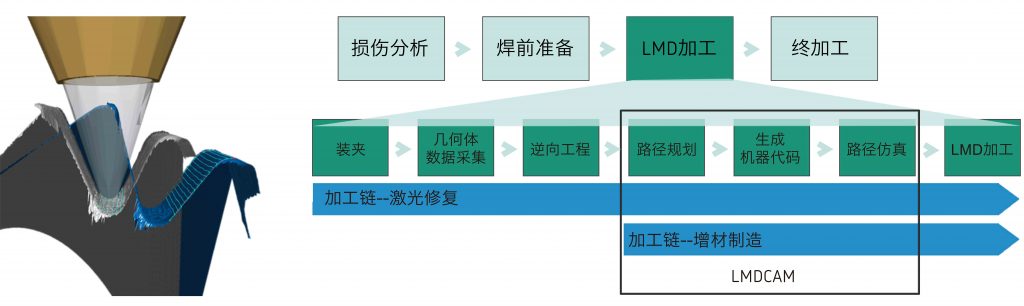

LMDCAM for professional laser direct deposition technology LMD Computer Aided Manufacturing CAM software for laser repair, cladding, additive manufacturing and other process of the auto-tiering and path planning.

LMDCAM software in the processing chain in the application

▏Software features

• Scan path design for laser additive manufacturing, laser repair, and laser cladding processes.

• Online scanning to obtain 3D data or build CAD models to optimize the machining process

• Multiple functions to set the processing vector of the processing path

• User-defined and modified coordinate system parameters, motion parameters, and process parameters

• The user-friendly graphical user interface to display faces, lines, and coordinate systems

• Script-driven post-processor to generate NC or robot code

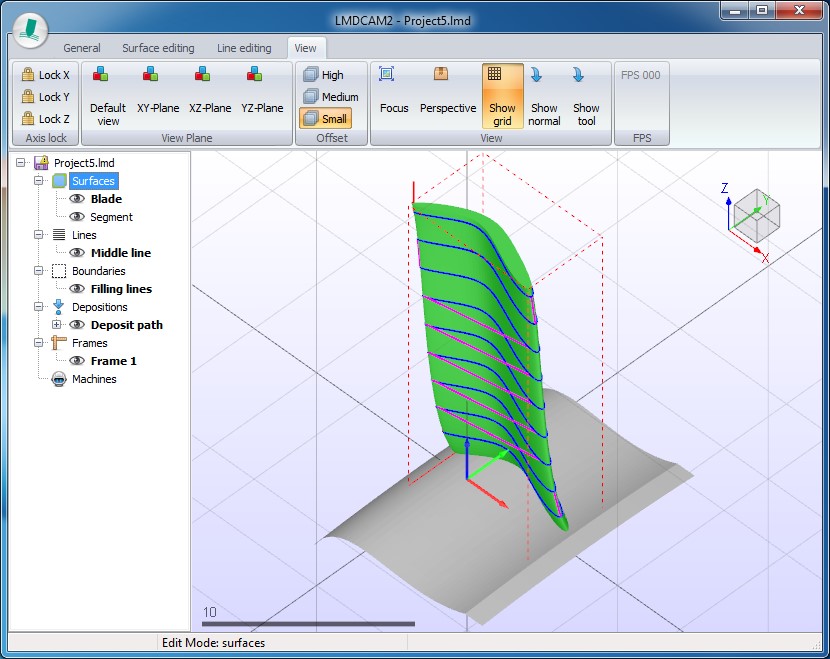

Parts of the laser additive manufacturing process

Software features

▏Software features

• Offline CAM program optimization for LMD machining processes

• Powerful path modification tool

• Enables fast manipulation of large data sets with triangular meshes

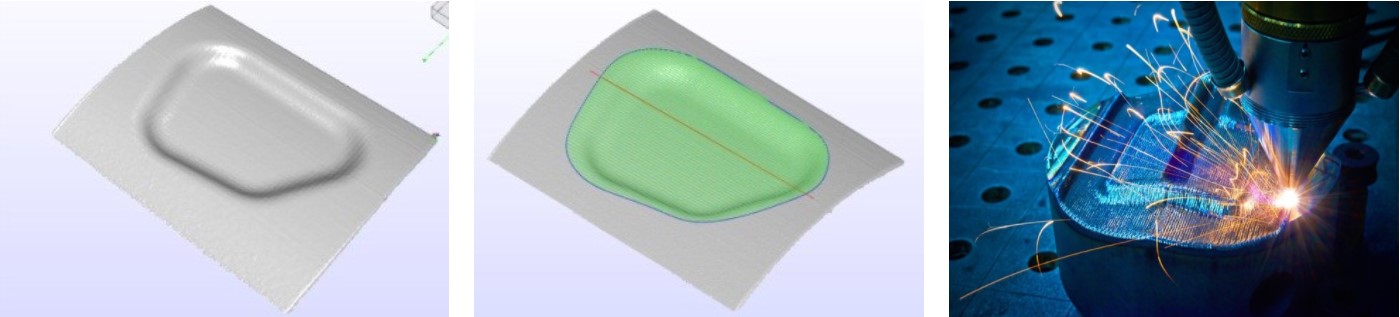

• Laser additive manufacturing process with the automatic layering of defined spacing planes to obtain contour and outer profile trajectories for additive manufacturing, with adjustable parameters for scan path direction, sequence, starting point, Etc.

• Laser repair process with closed isometric paths on the surface to be repaired and trimming of the ways using custom boundary lines or boundary surfaces.

• Automatic calculation of the centerline of the closed contour line

• NC code generator backend design to meet individual customer requirements

Damaged Blade automatic laser repair path design

Mold laser welding refresher cover