Inner cladding

Technology and procedure

• Highly adaptable solutions for the inner walls cladding

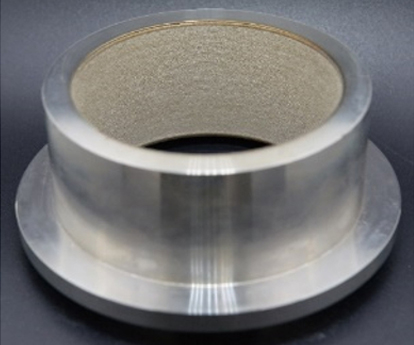

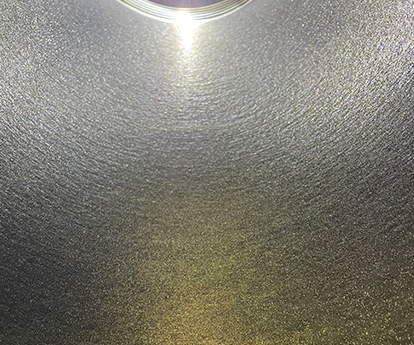

The demand for surface cladding and repair of the inner wall of some high load-bearing parts continues to increase, and it is desired to have excellent wear resistance, scouring resistance, corrosion resistance, Etc., such as bearings, molds, cylinders, oil cylinders, extrusion barrels, Valves, Etc. Furthermore, with the increase of product service performance and structural complexity, the industry is putting more and more demands on the applicable limit scale, multi-functionality, and high quality and efficiency of internal laser cladding and repair technology.

Unlike outer surface laser cladding, the laser beam, powder, and cooling water in the optic processing head must be transmitted over a long distance in a limited space. The inner wall laser cladding head requires high integration, precision, and rigidity to accommodate smaller and longer internal diameter parts.

ACunity the inner wall of the laser cladding process

▏Technical advantages

The demand for surface cladding and repair of the inner wall of some high load-bearing parts continues to increase, and it is desired to have excellent wear resistance, scouring resistance, corrosion resistance, Etc., such as bearings, molds, cylinders, oil cylinders, extrusion barrels, Valves, Etc. Furthermore, with the increase of product service performance and structural complexity, the industry is putting more and more demands on the applicable limit scale, multi-functionality, and high quality and efficiency of internal laser cladding and repair technology.

Unlike outer surface laser cladding, the laser beam, powder, and cooling water in the optic processing head must be transmitted over a long distance in a limited space. The inner wall laser cladding head requires high integration, precision, and rigidity to accommodate smaller and longer internal diameter parts.

ACunity the inner wall of the laser cladding technology parameters

Extra-long inner wall of the laser cladding head

▏Technology background

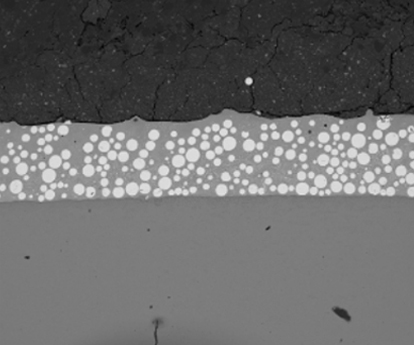

Inner Cladding Optics, also known as ICO (Inner Cladding Optics), is the core component of the inner wall laser cladding system. The optical system is continuously optimized and upgraded in terms of optical path design, lightweight structure rigidity, water-cooling effect, powder convergence performance, and integration, etc. It continues to push the limits in the range of maximum extension length and minimum applicable internal diameter, and can meet the demand of laser processing of internal holes and cavities of most sizes of parts in the industrial world. The modular system design and multi-series inner wall optical system can meet the different processing needs of inner wall laser cladding, laser repair, laser welding, laser hardening, etc. All materials suitable for outer wall laser cladding can be applied.

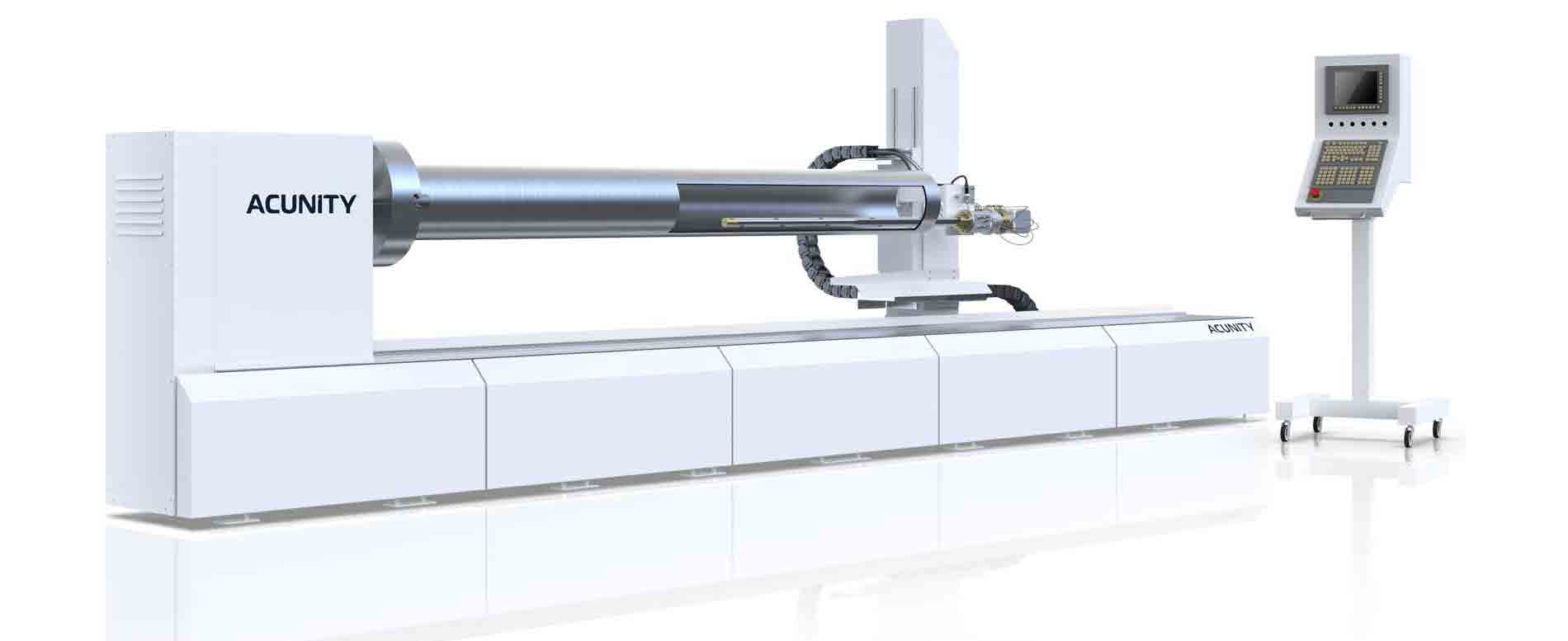

ACunity's inner wall laser processing system is designed with application convenience in mind. Therefore, the system adopts a modular design with different movement forms of machine tools and robots, equipped with other inner wall optical systems specifications, and allows integrated integration of inner and outer wall laser melting. At the same time, for different product characteristics and process requirements, the supporting process specifications for other methods of internal wall laser melting, repair, and hardening are developed.

ACunity the inner wall of the laser cladding system