Steel and Metallurgy

▏Needs of the industry

Steel and metallurgical equipment components in the production line service environment for most high temperature, high variable load, hot and cold alternating, corrosion, wear, and fatigue conditions. Some cast-iron parts are prone to corrosion and model and need to be replaced and maintained regularly in the use process. Especially in the production and processing of high-end automotive steel plates, the surface quality of rolls, transfer rolls, and other parts is very demanding. For this kind of part with high usage and high maintenance frequency, how to further effectively improve the service life and reduce maintenance costs is crucial to the development of the industry. The current surface protection layer of steel and metallurgical equipment parts are prepared mainly by electroplating, thermal spraying, arc overlay welding, and other methods. The application of laser cladding technology can more effectively improve the service life of the parts coating, reduce maintenance links, both in terms of coating thickness, coating performance regulation, and other aspects that have greater flexibility.

▏Laser Solutions

• EHLA

EHLA can offer the efficient preparation of wear-resistant and high-temperature resistant coatings on the surface of different sizes of shaft parts such as rolls, process rolls, and transfer rolls. Compared with conventional laser cladding, the heat input and the thermal influence on the substrate material are minimized. So that when we repeated repair and re-processing, there will be no resistance caused by the substrate heat-affected zone; another significant advantage is that the hardness of the coating surface is evenly distributed.

• Conventional laser cladding repair

Conventional laser melting can be used for surface coating preparation of oversized and overweight shaft parts and repair and remanufacturing of locally damaged parts. For example, blast furnace nozzle, large circular saw universal joint sleeve, flat head sleeve, crosshead, gearbox of reducer, Etc.

▏Laser Application Cases

• EHLA for cold rolls

As a major essential component of a rolling mill, the surface quality of cold rolls has a significant impact on the quality and productivity of the rolled steel. The hard rolls experience cyclic and thermal cycles during the rolling process, and the surface will produce oxidation, cracks, wear, and even broken rolls. Using ultra-high-speed laser cladding technology, the alloy, ceramic, composite cladding powder is treated by laser beam and melted together with the metal on the surface of the cold rolls, solidifying into a cladding layer with excellent performance, whose surface hardness can reach more than HRC65, providing a guarantee for the cladding layer to obtain excellent wear resistance, corrosion resistance, fatigue resistance, and high-temperature resistance, and achieving the purpose of saving precious materials. Therefore, the ultra-high-speed laser cladding technology is suitable for the surface repair of such local wear, impact, spalling, and oxidation corrosion of rolls.

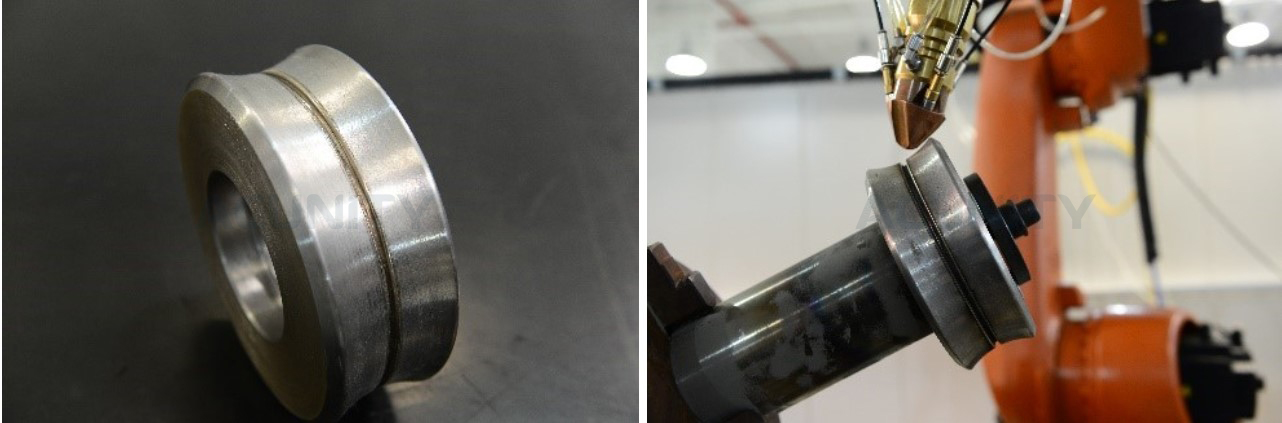

• Conventional laser cladding repair of guide wheel

Guide wheel is an essential spare part with high consumption in the hot rolled bar production line, which affects the mill operating rate and other technical and economic indicators. Many guide wheels have insufficient heat resistance, sticky steel, poor wear resistance, and thermal fatigue performance, which affect the service life and the quality of the rolled material. Laser cladding technology has the advantages of low dilution rate, small heat-affected zone, and easy automation of the process, which can be used to improve the wear resistance, corrosion resistance, fatigue resistance, and anti-cracking performance of the guide wheel. The general thickness of the cladding is only 1-3mm, and the hardness can reach HRC65 or more. After the cladding, the guide wheel can be put back into use, and the service life can be extended, which significantly saves the production cost.

Cold rolling Looper roller ultra-high speed laser cladding

Wheel conventional laser cladding

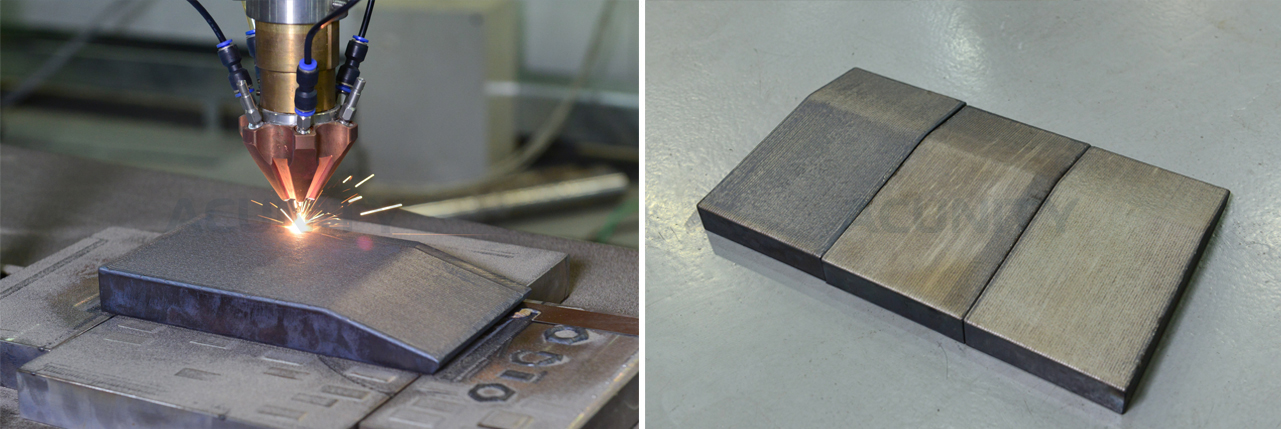

Wear plate laser cladding