Laser melting deposition

Technology and procedure

Laser melting deposition, also known as LMD Laser Metal Deposition, is a method based on laser cladding additive manufacturing technology, through layer-by-layer melt coating method, can produce a density close to 100%, the performance reaches and even exceeds the casting, forging parts, machining parts size depends on the processing system of the scope of work. Laser melting deposition technology can be used in the manufacture of gradient materials, composite parts, so that the performance parts and more diverse, the technology used in the function of the parts of the prototype manufacturing, product and small batch production, can also be applied to parts of the repair and surface modification.

• No mold

• Suitable for difficult-to-cut metal materials preparation

• High accuracy, enabling complex parts near net shape

• The internal organization of the fine and uniform, excellent mechanical properties

• May be prepared gradient material

• Can achieve damage parts of the quick fix

• Processing high flexibility, to achieve multi-species, variable-volume parts manufacturing rapid conversion

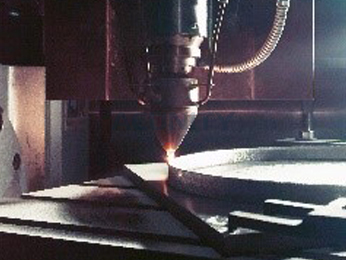

Laser surface modification

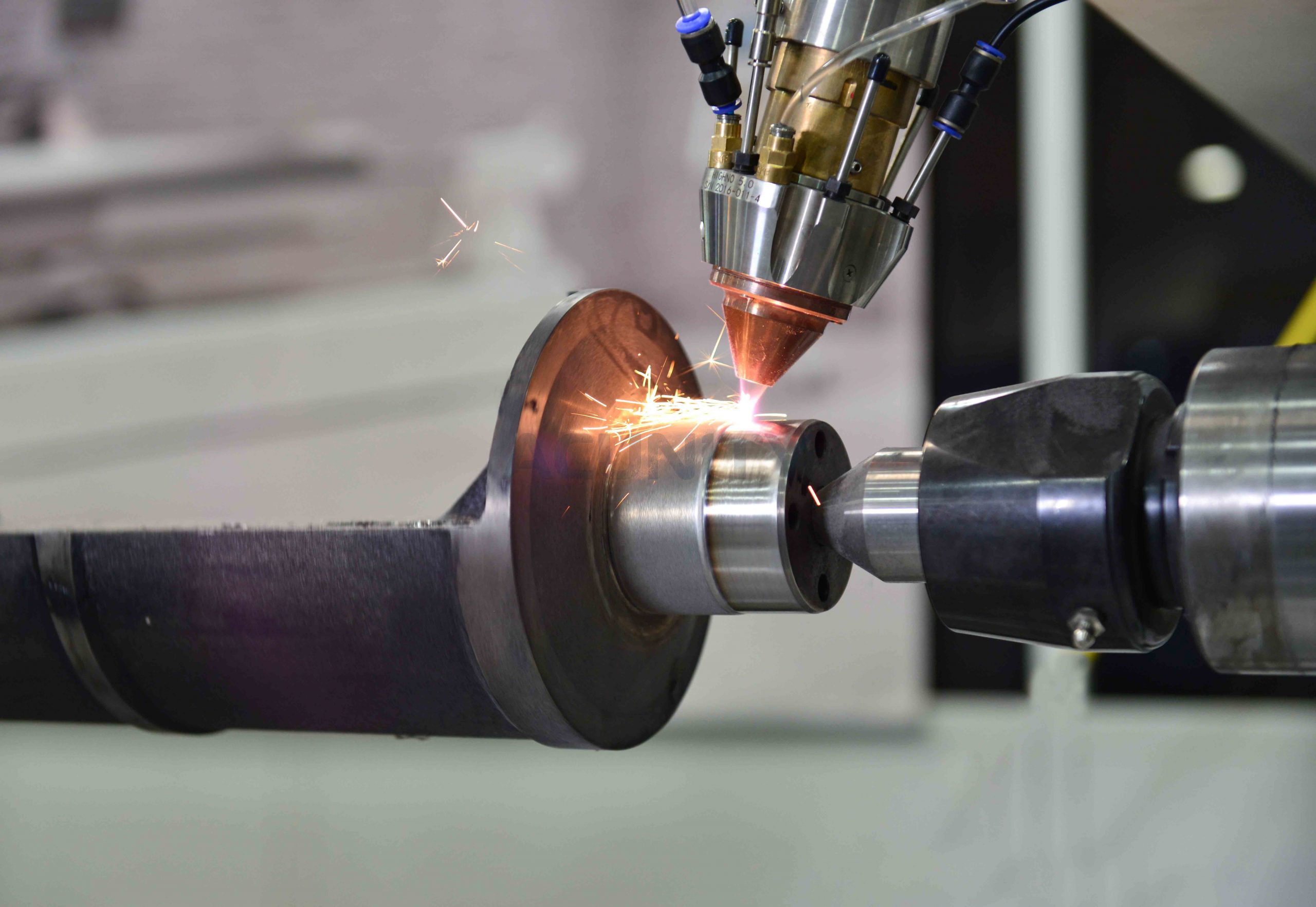

Laser repair

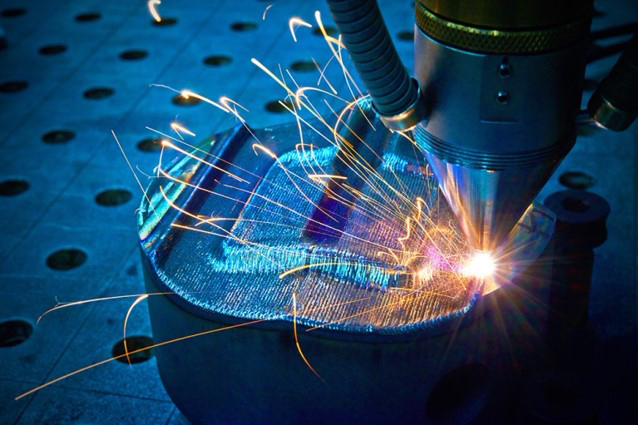

Laser additive manufacturing

▏Technical advantages

• Powder flow precision control: the series model of the cladding nozzle to meet precision, not to different application requirements

• Scan path automatic plan: LMDCAM layered software

• The deposition process online monitoring: to achieve the Weld Pool Image, temperature, reflected light real-time monitoring

• Thin-walled lightweight member a quick fix, manufacturing deformation control

• Highly reflective aluminum material direct laser deposition for additive manufacturing

• Material: Stainless Steel, high temperature alloy, titanium alloy, aluminum alloy, gradient materials, composite materials

Gradient materials manufacturing

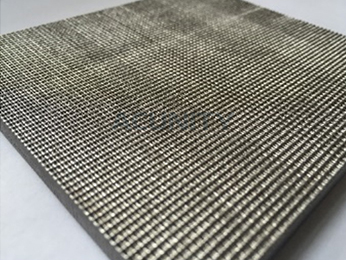

Grid structure

Spiral structure

Aluminum alloy shaped member