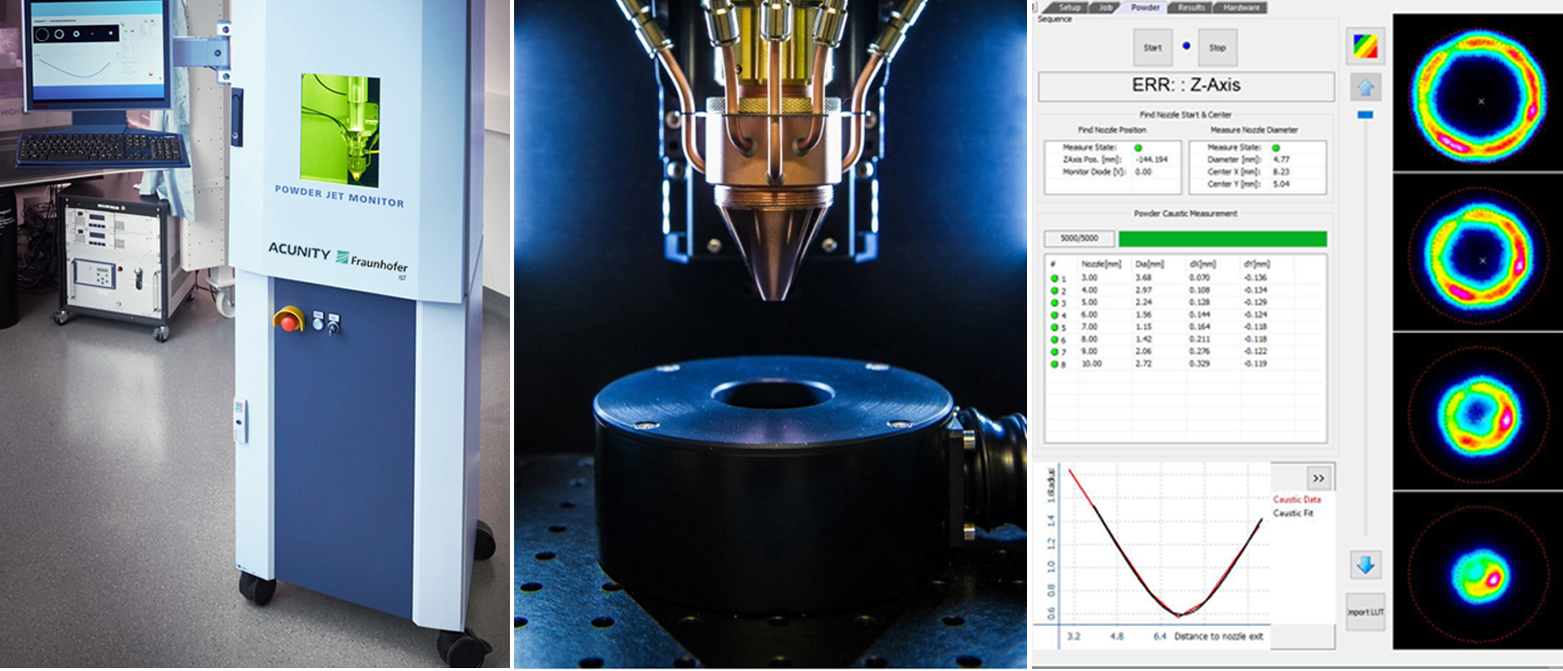

Powder jet monitor

In the laser melting deposition of metallic materials, the quality control of the powder stream is crucial. The way the powder enters the melt pool has a decisive influence on the process results and the product quality. The quality control of the powder stream can directly affect the powder utilization, deposition/coat oxidation, the geometry of the coated layer, and the surface roughness of the processed product. Therefore, powder beam flow needs to be measured, analyzed, and controlled to ensure excellent process quality and stability. ACunity offers you an intelligent series of equipment - Powder Flow Intelligent Inspection System, which is designed according to industrial application standards for powder beam flow testing of different types of coaxial nozzles, and automatically and continuously detects the powder flow status to provide assurance of quality processing processes.

▏Features

• The possibility of full-scale characterization of powder flows for the first time

• User-friendly operation interface

• Adaptable to different types of powder feeding nozzles

• Suitable for multi-stage powder size analysis

• Multiple test approvals

Powder jet monitor

The powder flow intelligent detection system obtains the concentration distribution of different sections of the powder flow by layer scanning, evaluates the nozzle working performance, detects the wear of the nozzle in the continuous operation process, and scientifically judges its service life. Furthermore, the high precision measurement method can quickly obtain the powder feeding gas, protective gas adjustment, and powder particle size on the powder flow convergence focus of the law to achieve accurate control of the powder feeding process and optimize powder material selection.

The system consists of a CMOS camera, test bench, illumination laser, analysis software, and other major core parts.

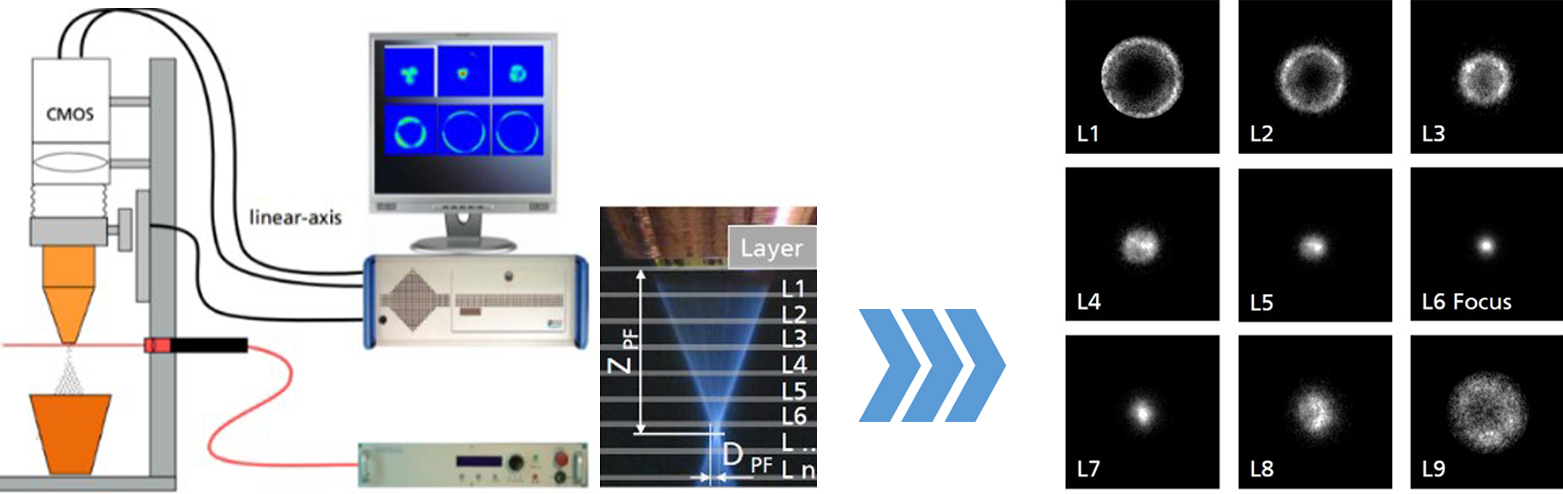

▏Measurement Principle

• Laser slicing method

• Thousands video frames per layer

• Powder particle density distribution per layer obtained by superimposing multiple frames of video

• 3D distribution characteristics of powder flow based on multi-layer information

• The number of layers and distances can be freely determined

• Calculation and analysis of feature images

Nozzle powder flow convergence characteristics of the detection principle

▏Measurement results

• Nozzle exit position

• Particle density distribution image for each layer

• Distance from nozzle exit to powder convergence focus

• Diameter of powder convergence focal point

• The relative position of powder focus and laser focus

• Effect of powder particle size on the emphasis of powder flow

• Influence of gas flow on powder flow focus

• Plotting the relationship between particle distribution diameter and nozzle distance

• Plotting the percentage of particles within each layer plane diameter (estimation of powder efficiency)

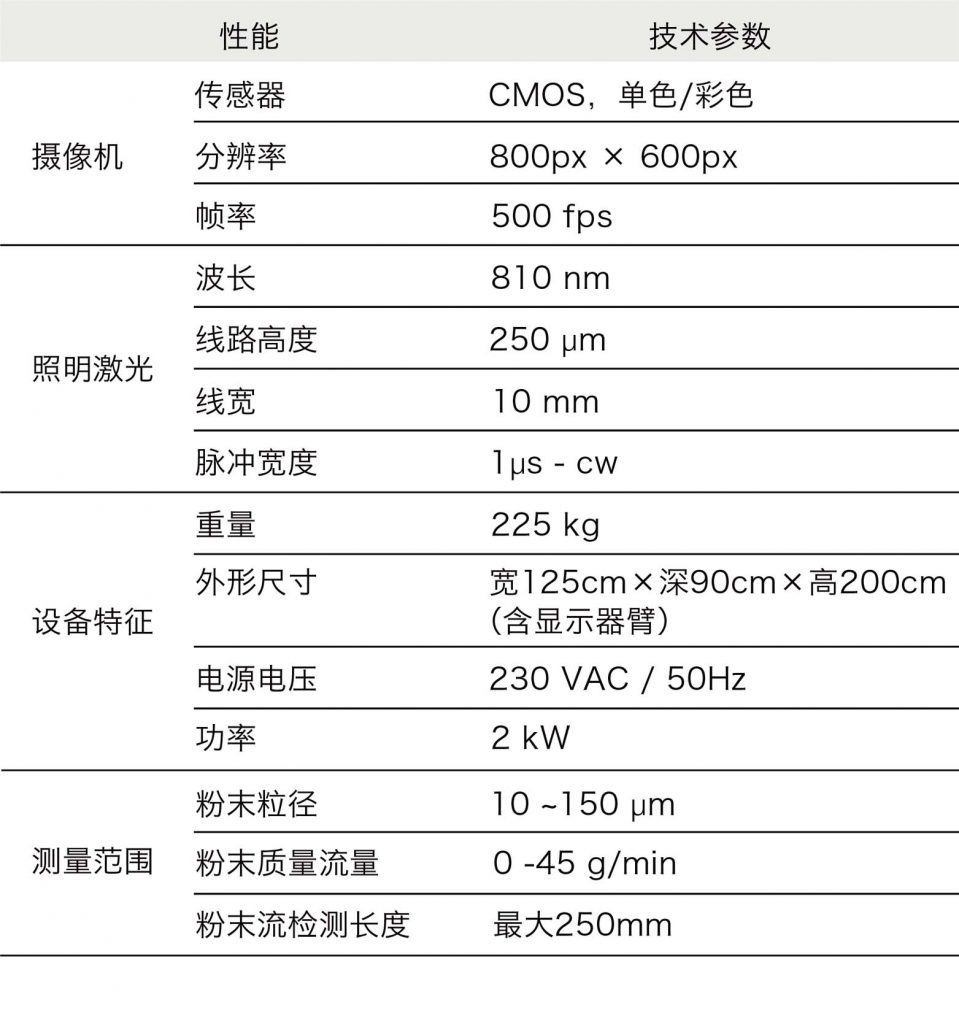

Powder flow intelligent detection system performance parameters