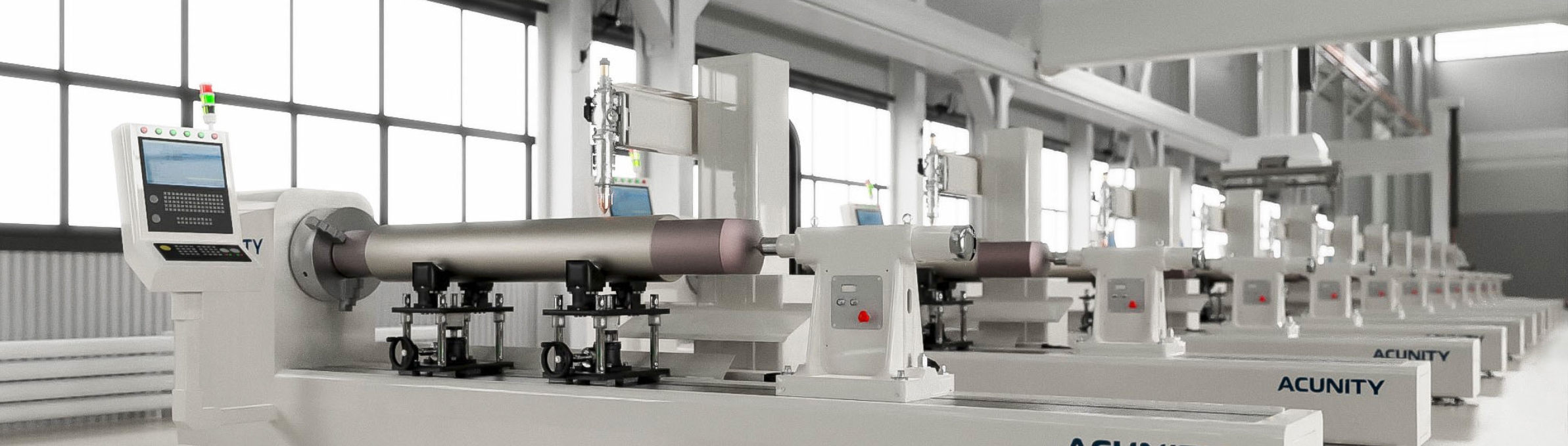

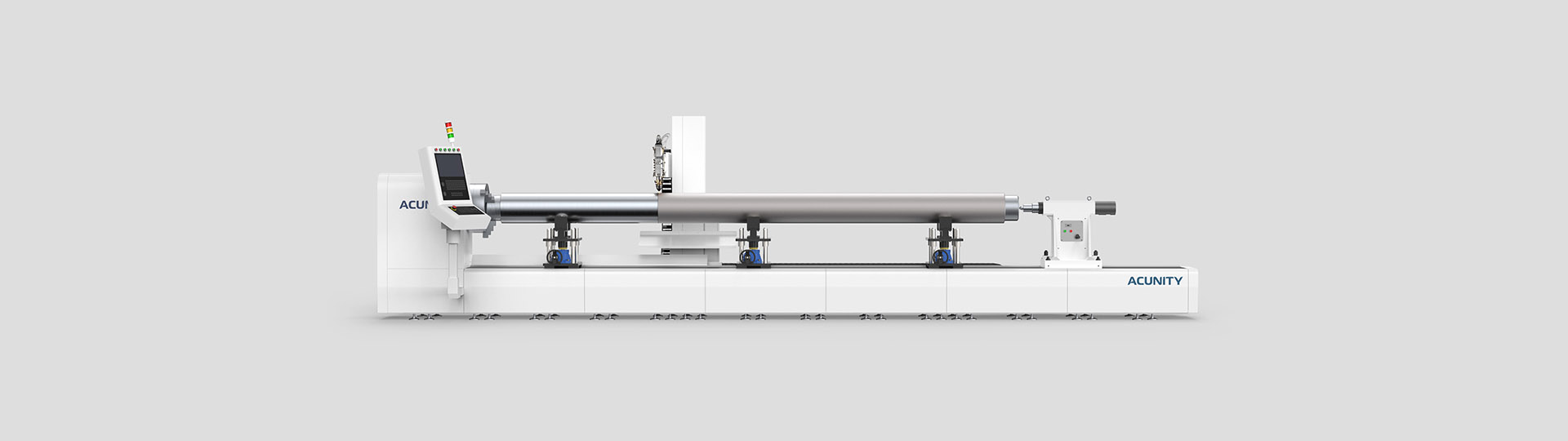

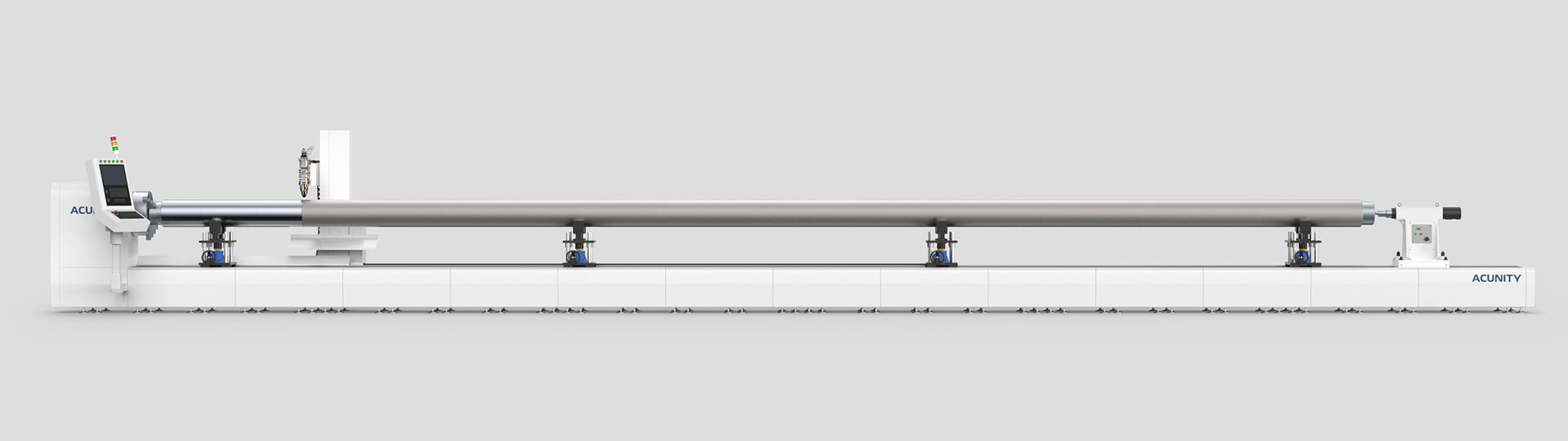

Extreme High-Speed Laser Metal Deposition System

EHLA System

Technology Highlights

Extreme high-speed laser metal deposition of rotationally symmetric components

EHLA technology is primarily used to enhance the wear resistance, corrosion resistance, high temperature tolerance, and oxidation resistance of part surfaces. This achieves the goals of surface modification or repair, fulfilling the requirements for specific surface properties of materials.

In the conventional laser metal deposition process, laser energy is used to melt the base material to form a molten pool into which the powder is injected and then melted and solidified to form a protective coating.

Extreme high-speed laser metal deposition technology fundamentally changes the melting point of the powder so that it intersects with the laser directly above the workpiece, allowing for uniform coating on the surface. With melting rates of up to 20-200 m/min, this technology is suitable for surface coating on heat-sensitive materials, thin-walled, and small components due to its low heat input. Moreover, it enables the preparation of coatings on completely new material combinations, such as those based on aluminum, titanium, or cast iron. The surface quality of the layer is significantly higher than that of conventional laser cladding and can be finished with a simple grinding or polishing process. This reduces material waste and the need for subsequent processing, making ultrafast laser cladding an indispensable application in terms of cost, efficiency, and thermal impact on the part.

Technical Advantages

Cost-effective

![]() Melt line speed 20-200m/min

Melt line speed 20-200m/min

![]() Cladding efficiency 0.8-1. 2m2/hr on Coating thickness

Cladding efficiency 0.8-1. 2m2/hr on Coating thickness

![]() Powder utilization ratio up to 95% or more

Powder utilization ratio up to 95% or more

![]() Follow-up without turning, can be directly grinded or polished

Follow-up without turning, can be directly grinded or polished

High Quality High Adaptability

![]() Hard stainless steel corrosion-resistant coatings achieve a hardness of over HRC 50 and have no corrosion pits

Hard stainless steel corrosion-resistant coatings achieve a hardness of over HRC 50 and have no corrosion pits

![]() Ultra-hard wear-resistant coatings can reach a hardness of over HRC 65, suitable for various types of surface

Ultra-hard wear-resistant coatings can reach a hardness of over HRC 65, suitable for various types of surface

friction and impact wear

![]() Suitable for a coating thickness of 0. 05-1mm

Suitable for a coating thickness of 0. 05-1mm

![]() High surface quality, the surface roughness can reach up to Ra 25 μm after cladding

High surface quality, the surface roughness can reach up to Ra 25 μm after cladding

![]() Suitable for a variety of material systems including iron-based, nickel-based, cobalt-based, copper-based,

Suitable for a variety of material systems including iron-based, nickel-based, cobalt-based, copper-based,

and composite materials

| Technical performance | Electroplate | Conventional laser cladding | EHLA |

| Cladding efficiency | / | 0.4-0.6㎡/h | 0.8-1.2㎡/h |

| Coating thickness | 0.01-0.15mm | 1-3mm | 0.05-1mm |

| Bond strength | Low, easy to peel, easy to peel off | High | High |

| Matrix thermal effect | Little | Large | Little |

| Processing deformation | Low | High | Low |

| Subsequent processing | / | Turning+grinding+polishing | Grinding+polishing |

| Environmental friendliness | Bad | Good | Good |

EHLA Series

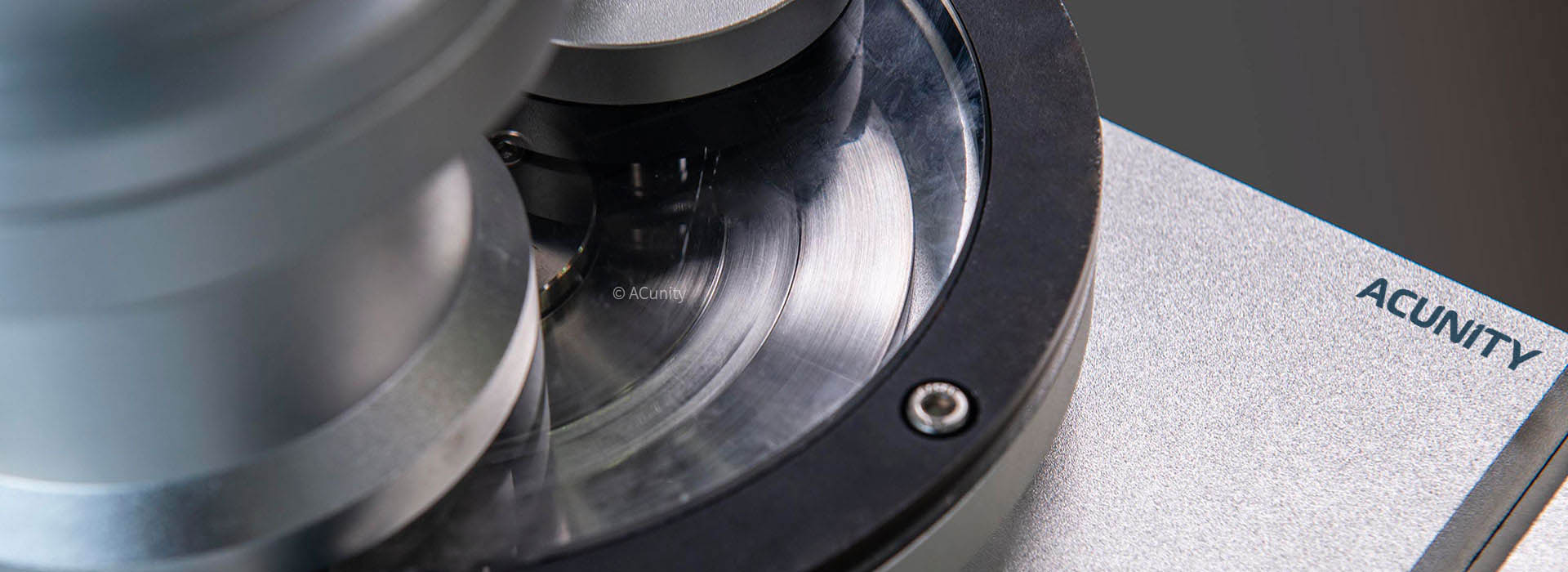

Laser Cladding Nozzles for EHLA

Based on traditional coaxial nozzles, ACunity has developed a new type of EHLA nozzle and registered a patent for it. The innovation includes a plug-and-play replaceable powder tip solution designed to meet the demands of industrial mass production for controlling the cost of wear parts and processing quality. The powder tip module features an integrated design, consisting of an inner cone and an outer cone. This module can be pre-assembled through corresponding shape and position tolerances for replacement without the need for manual adjustment. The gap size and wear resistance of the powder nozzle can be adjusted according to production requirements. The transition time for replacing the powder tip can be controlled within 1-2 minutes, offering high replicability of the process.

A Powder Feeder Tailored for EHLA Process

The laser metal deposition process of metal materials is influenced by many factors, such as processing materials, laser power, melting rate, protective gas, and powder feeding characteristics. The stability of powder delivery and the characteristics of powder flow convergence are one of the key factors determining the quality of the deposition layer and processing efficiency. Especially in large-scale production processes, the cladding nozzle is a very important consumable that undergoes long-term powder erosion, radiation of reflected light from the melt pool, and often directly affects coating quality due to damage to the flow channel and high-temperature powder sticking.

拷贝副本-17020899909.jpg)