Agriculture / Water Conservancy

Agricultural Machinery

During the cutting process of agricultural machinery equipment, the cutting tools must withstand impact and vibration loads, as well as strong friction between the workpiece and chips, resulting in frequent wear, rolling, chipping, or breakage of steel cutting tools during use, which affects machining accuracy and production efficiency, shortens the service life of the tools, and increases production costs.

Water Conservancy Equipment

Impurities or particles with high hardness can cause wear on the spiral during machine operation. Spiral with severe wear not only affects the normal operation of the equipment, but also accelerates the wear of other components, leading to a decrease in overall performance of the equipment and even early scrapping. Through laser cladding technology, local repairs can be made to the spiral surface, filling defects and cracks, extending service life, reducing the frequency of maintenance and replacement, and lowering operating costs.

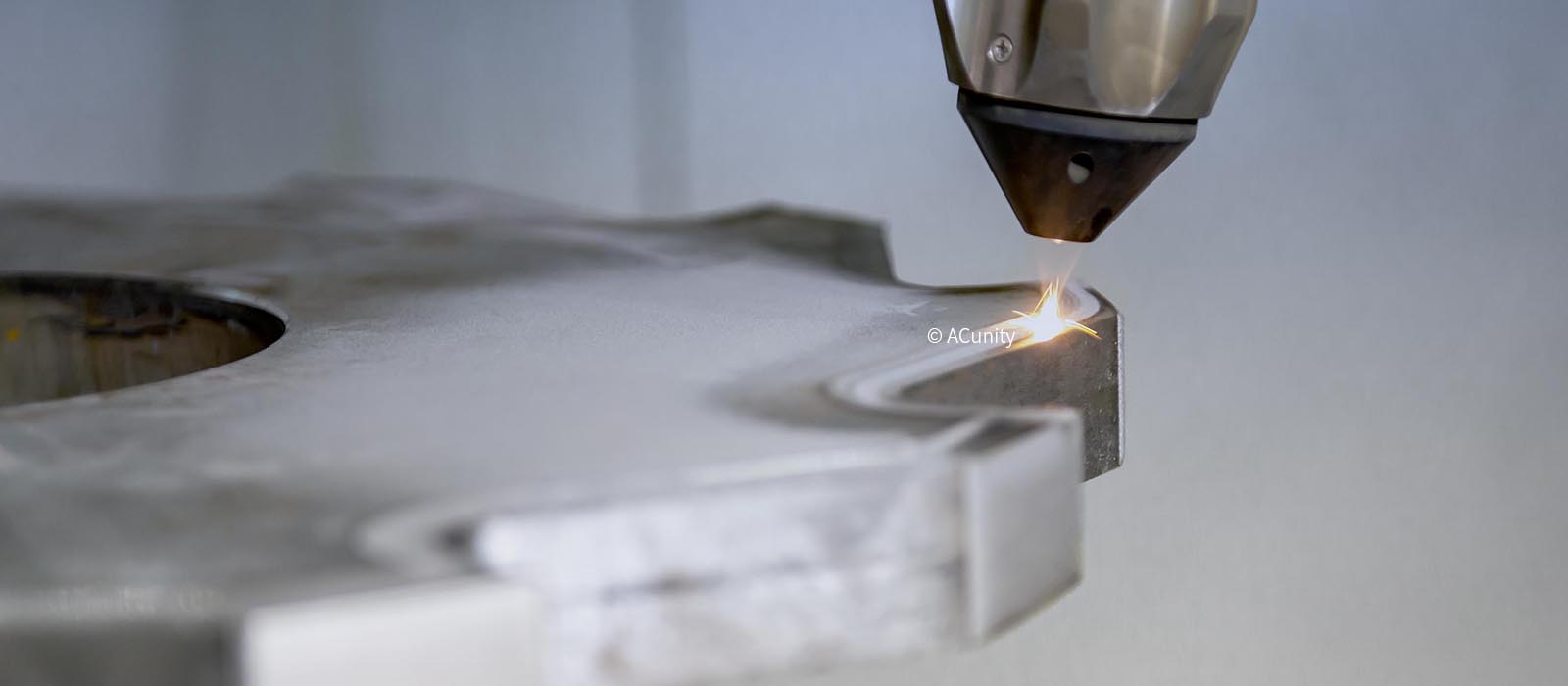

Application of Other Cutting Tools

The use of EHLA technology only requires the preset cladding material at the cutting edge of the tool to enhance the cutting edge band. Due to the small cladding area, precious metal materials can be saved, thereby reducing manufacturing costs. The cutting edge of the tool after simultaneous melting has high strength, hardness, and wear resistance while also possessing the strength and toughness of the matrix, which effectively solves the contradiction between the hardness and strength of high-speed steel tools and improves the cutting performance of high-speed steel tools.